We supply Granite Blocks, Granite Countertops & Vanities, Granite Cutter Slabs, Granite Gangsaw Slabs, Granite Monuments & Tombstones and Granite Tiles to our clientele worldwide.

Recognized Exporter of India Granite.

GRANITE PRODUCTS CATEGORY

PROCESSING THE GRANITE

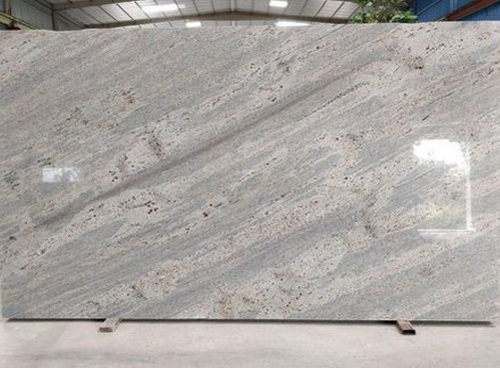

With a selection of more than 80 colors, from South and North India, the quarries are scattered all over. Our team members, personally visit these quarries to select the best quality Blocks as per the requirement of quality and colors. Granite is a natural material, at times the production of the blocks has more natural defects, having age old relations with the quarries directly helps us to select the best blocks at the most appropriate price.

Briefly, stone processing of blocks into slabs can be described as :

GANG-SAW CUT SLABS :

First, the blocks are dressed using wire –saw machine, so that the blocks are sawed on all 6 sides to check for quality and cracks. the blades are set in the gang- saw machine as per the size. The hardness of the color and thickness specification for cutting. For every slab we lose approximately 9mm of material, once the block is secured and moved into the machine for cutting, it may take from 24 hours to 60 hours for the processing to complete depending on the hardness of the material.

Depending on the size of the block, one block may work out to 300 to 450 Sq.mtr. of slabs(2 cm thickness). Once the slabs are cut , they are inspected for quality and natural defects and moved for further processing. The slabs processed can be of the sizes; Length; 250-350 cm, width;150-205 cm, thickness; as per requirement.

CUTTER SLABS :

Again, once the block is dressed, it is moved to the cutter machine. These machines mostly use circular saw blades-may be singular circular saw machine or multi-blade circular saw machine, one machine can process from 70 sq.mtr. to 1500 sq.Mtr.per day, depending on the number of blades in the machine. However, for processing slabs in varied thickness, only a single blade machine can be used. The slabs processed can be of the sizes; Length;180-350cm, Width;60-100cm, Thickness; as per the requirement.

A distinctive blend of experience, technology, focus and access to the best minerals enable us to deliver an infinite and exquisite range of colors and shades at modest prices and matchless quality. Customer preferences are of paramount consideration…

Range of colors and materials available with Sheravis marvelous and really infinite. Most of the colors and patterns we deal in granite gives a rich, natural look.

AVAILABLE SIZES

Gang-Saw Cut – Random Slabs 280up × 180up × thickness. Standard Thickness Processed 2 cm and 3 cm – 4 cm to 10 cm thickness available upon request.

Random slabs – 220up × 110up × thickness. standard thickness processed 1.8 cm – 2 cm to 8 cm thickness available upon request.

Tiles – Standard sizes; 30× 30 ×1cm, 60×30× 1cm, 60× 30 × 1.8cm or 2cm, 60× 60× 1.8cm or 2cm.

Cut to Sizes – Thickness can be processed from 1.5 cm to 8 cm as per requirement. Slabs are processed into Tiles as per the specifications provided with utmost accuracy

As we are regularly doing projects, we are well versed with the whole process;

- Selection of raw materials per our choice of material and with minimum natural defects as far as possible. planning of production as per the set and realistic terms.

- Cutting of blocks into slabs, maintaining the thickness as per the standards of the projects.

- Finishing of slabs-Polished/Flamed/Honed/Leather/Sand-blasted with latest finishes as per project requirements.

- Cutting of slabs into tiles or cut to size, as per the specifications of the project. The sizing process is the most important process and must be handled properly so that there are no variations in the sizes of the finished tiles. All tiles are checked for quality and size again before the final packing takes place.

LABELING – For any projects, the easiest way to work with granite tiles is labeling. As we will be provided with the details about the projects and also, about which batch is for which area in a project, we fix stickers on all tiles indicating the sizes, area of application, finish and other relevant details. Finally, a summary is fixed on the wooden crate for easier access to the construction staff at the site.

PACKING AND FORWARDING – The final step, the packing of goods into strong and well-designed wooden crates. We can’t afford to waste good material just due to bad packing. We have our fixed shipping agent with whom we are working from 2006, and direct contact with the Maersk shipping line. This way we can avoid any delays and the best cost possible.

TIME FOR DELIVERY – As in most projects, the time of delivery of goods plays a crucial part. As we are direct processors, so any delay due to middleman is already avoided. we will provide you a delivery schedule, certainly in consultation with our client, and we can assure you that we can stick to that delivery plan on the whole. It’s important to set the time schedule realistically, rather than committing to a faster delivery schedule just to bag an order. Everything must be planned, including the raw material, processing, packing, forwarding so that the delivery schedule is met and we have done this work several times already, we are confident about this work

PACKAGING & LOGISTICS – According to the Packing & Logistics, we everything must be planned, including the raw material processing, packing, forwarding. So that the delivery schedule is met and as we have done this work several times already. we are confident about this job. our material handling department is manned by trained personnel who follow safety guidelines and also to dispatch schedules. All packing and forwarding activity is carried out in the house, in conformity with the strictest quality standards.

Quality compliance – It is our constant endeavor to maintain and enforce quality control measures at all times. we have a system of rigorous examination of our products for quality compliance before they are approved for production /processing.

Quality Check – We have a team of material inspection agents to examine for quality compliance and check delivery parameters-as per client’s requirement.

Safe dispatch – We ensure the safety of the material in transit. we ensure proper packing , crating and stuffing and dispatch of cargo.

Uncompromising quality commitment and customer value creation with utmost integrity and sincerity towards all relations.

Values and Beliefs;

- Value creation

- Honesty & Transparency

- Excellence in service

- Team spirit